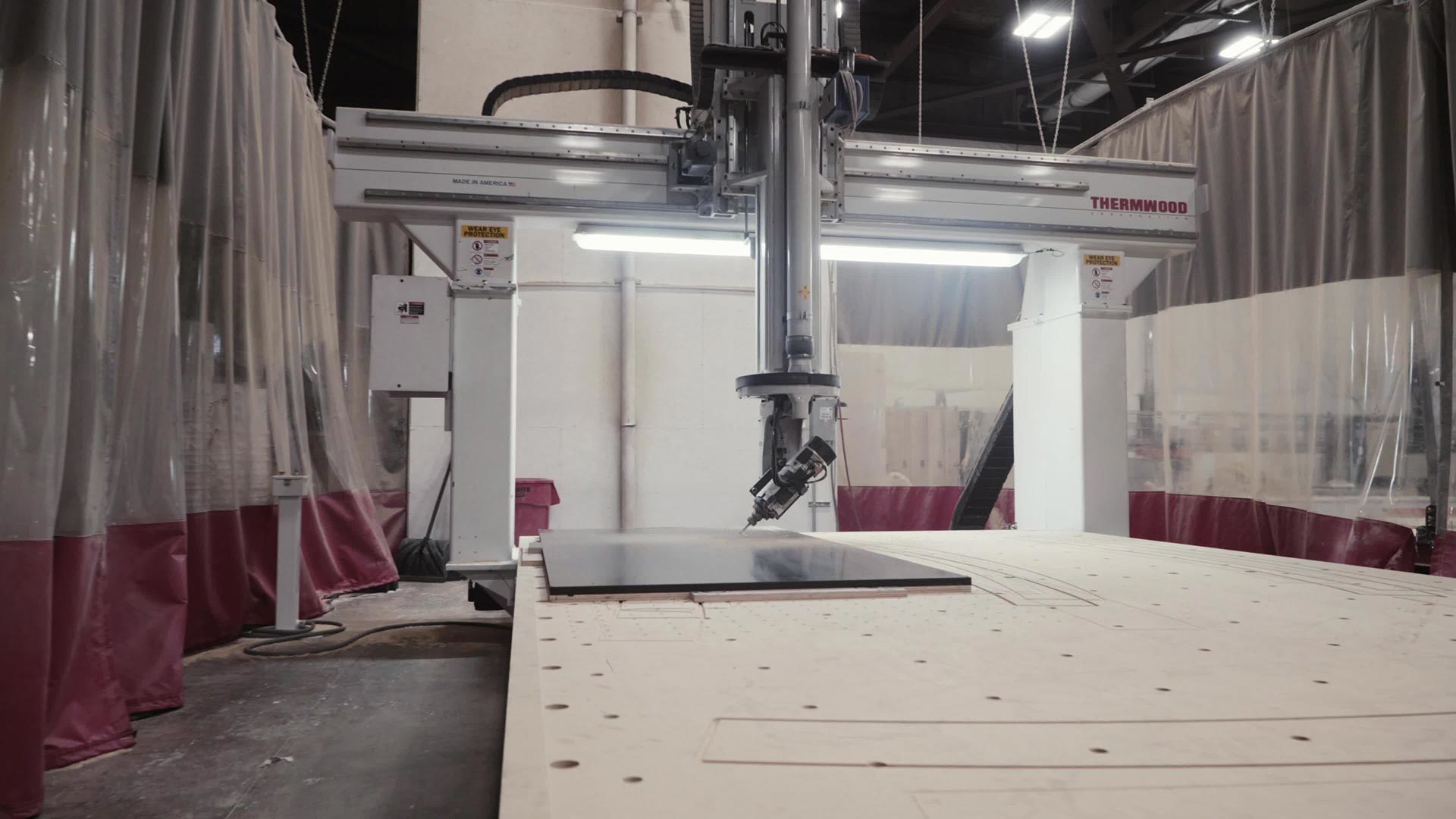

Scott System uses CAM software to control the CNC machine, which allows us to develop and produce parts that are a variety of shapes and sizes. The largest machine has a production envelope of 4’ high x 10’ wide x 15’ long and can handle very large parts with the ability to index and restart programming.

Our Capabilities

Our 5-axis milling process utilizes CAD/CAM subtractive manufacturing techniques in a production sequence.

This means that bulk material is placed on our machine and the router removes the materials in two steps: rough pass and finish pass.

The design team at Scott System uses CAM software to control the direct cutting of the CNC machine, which allows us to develop and produce parts in an array of shapes or sizes to fit the project as needed.

The machines in our arsenal are capable of milling 120-inches on the x-axis, 180-inches on the y-axis and 48-inches on the z-axis.

We also have the capability to mill non-ferrous metals like aluminum, varieties of foam, wood, and even composites.

Quality Control

Our design team has a built-in system of checks and balances within the design and manufacturing process to ensure quality control is met each time.

Digital Design gives us the flexibility of manufacturing a part of our CAD/CAM software before the material even reaches our production floor.

Then the design process verifies part fabrication, tool path of the machine to avoid collisions, and generates lead times.